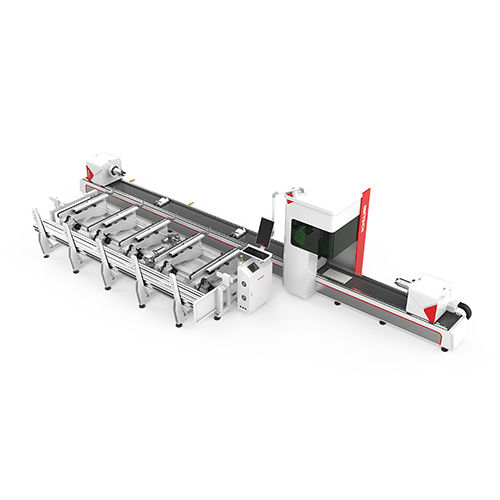

TL Affordable 1kw Fiber Laser Tube Cutting Machine Price

Product Details:

- Product Type Tube Fiber Laser Cutting Machine

- Laser Type Fiber Laser

- Material Metal

- Cutting Thickness 0.5-25 Millimeter (mm)

- Cutting Area 15153030 Square Millimeter (mm2)

- Cutting Speed 100 m/m

- CNC Or Not CNC

- Click to View more

TL Affordable 1kw Fiber Laser Tube Cutting Machine Price Price And Quantity

- 1665433.00 INR/Set

- 1665433.00 - 2498149.50 INR/Set

- 1 Set

TL Affordable 1kw Fiber Laser Tube Cutting Machine Price Product Specifications

- 1000-6000 Watt (w)

- Metal

- Semi Automatic

- 2500 Kilograms (kg)

- White

- 2600*1920*1980 Millimeter (mm)

- 2 Years

- Tube Fiber Laser Cutting Machine

- Fiber Laser

- DXF

- 0.5-25 Millimeter (mm)

- Au3tech

- Water Cooling

- Touch Screen Simple Control High Performance ECO Friendly Lower Energy Consumption

- 100 m/m

- Yes

- 15153030 Square Millimeter (mm2)

- CNC

TL Affordable 1kw Fiber Laser Tube Cutting Machine Price Trade Information

- Qingdao

- Paypal Delivery Point (DP) Telegraphic Transfer (T/T) Western Union Letter of Credit (L/C)

- 100 Set Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- CE, FDA, ISO9001, SGS

Product Description

1. With the excellent metal tube clamping system, the machine can stably convey the metal tube and manufacture high-quality and high-precision products. It can also be equipped with a slag removal device on the inner wall of the pipeline.

2. The tube-cutting machine adopts a gantry bridge structure to ensure stable operation and prevent deformation. Equipped with a gantry protective cover to prevent laser burns and smoke injuries, ensure the safety of operators, and protect the environment.

3. The machine uses the world-class Raycus/Max laser source to release high-quality laser beams for precise processing of materials. The cutting edge is flat and smooth without any burrs.

4. The machine increases the height of the material loaded on the bed, which is more ergonomic and convenient for the loading process.

5. The pneumatic chuck can automatically adjust the center, which is suitable for pipes of various shapes. The high rotational speed of the chuck improves the processing efficiency.

6. The machine can perform various 3D processing effects such as hole cutting, arc cutting, engraving, and slotting on metal tubes, and can process various special-shaped metal tubes, such as rectangular tubes, oval tubes, square tubes, round tubes, etc.